Ergonomic Evaluation of Workstations in a Metalworking Company – Quantification of Musculoskeletal Risk and Suggestion of Occupational Measures Implementation

Costa de Almeida MJ1,*, Simões J2, Almeida L2

1Occupational Medicine researchers at Centro Hospitalar Universitário do Porto, Portugal

2Medical Specialist in Occupational Medicine, Portugal

Received Date: 21/01/2023; Published Date: 27/02/2023

*Corresponding author: Maria José Costa de Almeida, Occupational Medicine researchers at Centro Hospitalar Universitário do Porto, Serviço de Saúde Ocupacional, Largo Prof. Abel De Salazar, 4099-001 Porto, Portugal

Abstract

Ergonomics is the scientific discipline that studies the interactions between human beings and other elements of a system applying theory, principles, data and methods to optimize well-being in the general performance of a function. This knowledge was applied in a metalworking industry, in 14 workers who perform grinding, allowing to quantify the musculoskeletal risk of this task. For this, the Ovako Working Posture Analysis System (OWAS method) was used, through the Ergolandia® plataform. By characterizing the jobs, it was possible to implement preventive and some corrective measures.

Keywords: Ergonomics; Metalworking; Deburring; OWAS; Work-related musculoskeletal disorders

Introduction

In the European Union, in 2017, 2.912 accidents at work resulted in the death of workers. Portugal is the fourth country in the European Union with the most fatal accidents per 100.000 workers [1]. Accidents at work are a global problem with very serious economic and social consequences. On the other hand, continued exposure to occupational hazards can lead to the development of occupational diseases. EU-OSHA's Third European Survey of Enterprises on New and Emerging Risks (ESENER-3) directly asked workers in 45.420 companies from all sectors of activity about Safety and Health regarding how risks are managed in their workplaces; practically 60% do not have an expert who deals with ergonomic design and configuration of the workplace, 43,5% do not have access to ergonomic equipment such as specific chairs or desks [2].

Both accidents at work and prolonged sick leave could be avoided if they were anticipated and if safety measures were implemented and strictly followed. Occupational Health and Safety is an area that, as it deals directly with human lives, is of tremendous importance, and this is also the assumption behind the legal framework that regulates it [3,4]. According to statistical data from the Strategy and Planning Office of the Ministry of Solidarity and Social Security for 2020, published in March 2022, for the economic activity related to “Skilled metallurgy, metalworking and similar workers”, the following were registered: 15.021 work accidents, of which 5 were fatal; verifying that workers in the metalworking industry, nationwide, run a relatively low risk of death, but are among those most exposed to the risk of non-fatal accidents [5].

This sector of activity, specialized in the manufacture of metal-mechanical constructions for heavy industry, metal constructions for public works, structural construction of locksmiths and industrial maintenance, has an enormous economic and social importance in Portugal – it is dynamic and has high employability in Portugal, despite the enormous difficulty in recruiting qualified labor. In the company under study, the identified ergonomic risks were: excessive and continuous efforts, inappropriate postures, repeated movements, prolonged osthostatism and use of Display Screen Equipment (DSE).

The intervention plan for ergonomic risks is fundamental and therefore it is necessary to continuously identify and assess the risks in time and space (signposting the jobs most often associated with complaints related to Work-related Musculoskeletal Disorders (WMSDs), evaluation of the exposure to risks with the application of ergonomic assessment methods) to make it possible to apply corrective measures at the workstations level, in accordance with the proposals resulting from the ergonomic assessments [6].

Organizing work so that workers can perform more than one activity in an alternate posture (standing/sitting), adapting PPE and continuous monitoring of workers health are joint tasks of the Occupational Physician and the Health and Safety Technician.

Materials and Methods

The chosen company operates in the field of metalworking, specializing in the manufacture of metalworking constructions for heavy industry, metal constructions for public works, structural construction of locksmiths and industrial maintenance. It has 195 workers, of which 188 are males, aged between 18 and 72 years old (with a dominant age group between 18 and 49 years old). 14 workers, males, responsible for the grinding task were studied.

The collected data was analysed and treated in the Ergolandia® software. The method used for the evaluation was the Ovako Working Posture Analysis System (OWAS). The OWAS classifies postural loads for the urgency of corrective actions into four Action Categories (AC).

Results

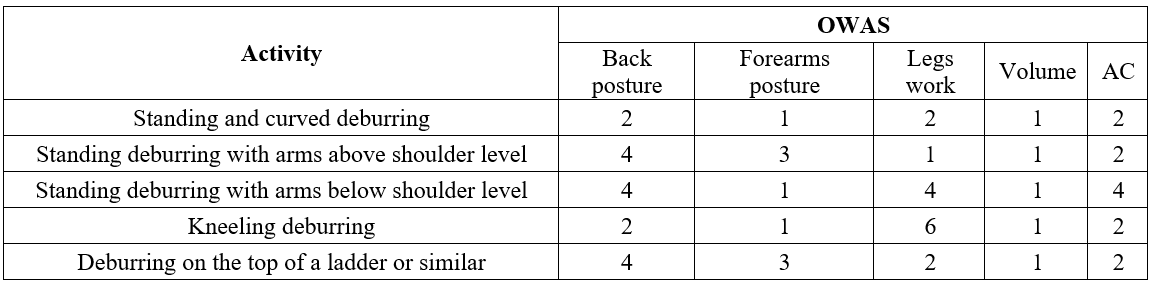

OWAS was developed in Finland in a steel industry company, Ovako Oy, in 1973 to describe the workload in the overhauling of iron smelting ovens. OWAS identifies the most common work postures for the back (4 postures), arms (3 postures) and legs (7 postures), and the weight of the load handled (3 categories). Whole body posture is described by these body parts with a four digit-code:

1 – back posture: 1 upright; 2 leaning forward; 3 flexuous; 4 leaning forward and flexuous

2 – forearms posture: 1 both below elbow joint; 2 one above elbow joint; 3 both above elbow joint

3 – legs work: 1 sitting position; 2 standing with legs upright; 3 standing with one leg upright; 4 standing with legs bent; 5 standing with one leg bent; 6 kneeling on one or both knees; 7 walking

4 – external load volume for men (kg): 1 below 10; 2 within the range 10-20; 3 above 20

OWAS does not have any kind of underlying mathematical model. Instead, it relies on a lookup table that converts three-digit posture codes into Action Categories (AC)

OWAS action categories were derived based upon work postures and loads managed for each job-task. The posture evaluation method developed in this study was implemented as a computer software program incorporating a timer, called Ergolandia®, which can be used to measure the observation phasing. The system was designed to automate all the procedures for the analysis of the postures, except for observing the postures and recording them according to the postural classification.

Discussion

The production process, which uses iron as the main raw material, often resorts to deburring for cutting off for minor rectification. The angle grinder is risk-enhancing equipment as it needs human intervention.

Action Categories (AC) classifies the relative risk and urgency for intervention to prevent musculoskeletal disorders due to exposure. Of the studied workers, only the task of “Standing deburring with arms below shoulder level” had an AC 4, with all other tasks having results of an AC 2, which means that is necessary to apply corrective measures in all of the postures.

It has been found that workers who deburr standing with their arms below shoulder level, work with curved spine, curved neck and bent legs. It was proposed to correct this situation with the acquisition of lifting tables, adjustable in height.

In addition, it was recommended to acquire PPE suitable for the task, task rotation (organize the work in such a way that it is possible to carry out more than one activity in an alternate posture), regular breaks during the working day and carrying out a training action in ergonomics.

The Occupational Physician must also:

I – Carry out the worker’s anamnesis, contemplating:

- Complete clinical examination

- Family and personal history

- Trauma history (at work or not)

- Rheumatic diseases

- Presence of risk factors for WMSDs in extra-work activities

II – Analytical exams

- Complete blood count: leukocytosis may be indicative of an infectious process; some may mimic symptoms of WMSDs

- In the absence of other infectious or rheumatic symptoms: CRPv or CRP measurement (inflammatory process)

- Urine summary: isolated hematuris, after ruling out other pathologies, may be indicative of overexertion

III – In the case of suspected WMSDs, auxiliary diagnostic tests should be performed:

- X-ray of the osteoarticular regions in question, in order to assess possible bone alterations, alterations compatible with arthrosis or eventual tendinous calcifications compatible with chronic inflammatory processes

- Ultrasound of the soft parts of the joint regions in question, in order to allow the evaluation of superficial structures, usually tendons, ligaments and muscles. Ultrasound allows diagnosing inflammatory processes such as tenosynovitis, tendinitis, myotenosynovitis, periarthritic processes, condylitis and bursitis

- Magnetic resonance imaging, for more accurate diagnoses, for example in cases of subacromial bursitis

- Electromyography to assess the conduction velocity of nerves potentially affected by compressive pathology

Finally, it is necessary to focus on training and informing workers about the results of ergonomic assessments, ensuring continuous training on proper working postures and to minimize the risks of musculoskeletal problems.

Conclusion

It is only possible to adapt the worker to his job by knowing the machines and tools used, how they work, what they are for, at what stage of the process they are used and what risks they entail. It is part of the “field work” of an Occupational Physician, outside the doctor’s office, to know and understand the complex dynamics worker-machine-ergonomics. The use of the angle grinder proved to be an activity that involves greater effort at the level of the upper limbs. A key point in this activity is the time that each worker is exposed, in some cases, during eight hours of work per day, reconciling the ergonomic risk, the vibration transmitted to the hand-arm system and the noise caused by the use of the equipment.

The prevention of WMSDs is only possible through a study of the production cycle and correction of any inappropriate postures adopted by workers in carrying out their tasks, reviewing and correcting procedures thar imply repeated and excessive efforts.

Author Contributions

Maria José Costa de Almeida: guarantor, selection of the theme, research and references review, writing

Jorge: co-authorship

Luís Almeida: scientific review; final approval

Conflicts of interest: The authors disclose any conflicts of interest.

Grant Information: The authors received no specific funding for this work.

References

- Are EU citizens safe at work? ec.europa.eu, 2021.

- European Agency for Safety and Health at Work. Third European Survey of Enterprises on New and Emerging Risks: Overview Report How European workplaces manage safety and health | Safety and health at work EU-OSHA. osha.europa.eu, 2022.

- Decreto de Lei n.º 7/2009, de 12 de Fevereiro (artigos 281.º e 282.º do Código do Trabalho). Lisboa: Diário da República. Assembleia da República.

- Decreto de Lei n.º 102/2009, de 10 de Setembro (artigos 73.º a 110.º). Lisboa: Diário da República. Assembleia da República.

- Gabinete de Estratégia e Planeamento (GEP) Ministério do Trabalho, Solidariedade e Segurança Social (MTSSS). Quadros de Pessoal COLECÇÃO ESTATÍSTICAS, 2020.

- Coentro S. Prevenção e Segurança no Trabalho em Industria Metalomecânica, 2018.

- Paim C, Peraça D, Sapper F, Moreira I. Análise ergonómica: Métodos RULA e OWAS aplicados a uma instituição de ensino superior, 2016.